Markon’s Food Safety Director offers vital tips on managing the natural gas that ripens fresh produce.

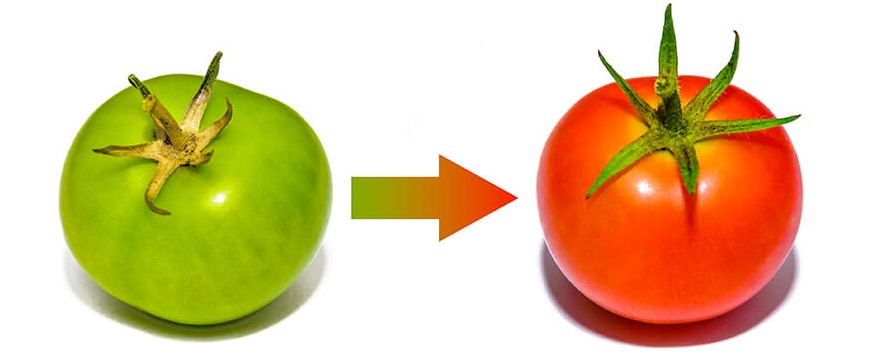

It takes a lot to produce a perfect banana – that bright yellow and spotless peel that indicates the fruit inside is ripe and ready to eat. A key ingredient is ethylene, an odorless, colorless gas generated naturally to ripen not only bananas, but also the likes of apples, avocados, cantaloupe, pears, stone fruit, and tomatoes.

Ethylene’s impact is so profound that one must be careful when storing fruits and vegetables in coolers. According to the USDA, produce sensitive to ethylene shouldn’t be stored near produce that produces it because it can affect product quality, leading to increased spoilage.

To improve shelf life, simply store produce separately. For example, “ethylene sensitive produce” such as broccoli, cabbage, and leafy greens should not be stored next to “ethylene producers” avocados, melons, bananas, and tomatoes. Yet ethylene may also be used effectively to ripen produce to perfection as well. It can help with the ripening process to ensure that produce hits the operator kitchen or retail shelf in mint condition.

To illustrate, Markon has created a Short-Term Produce Storage Guide to help operators identify where to store produce at the proper temperature to maximize shelf-life. Additional best practices may be found in the Resources and Tools section, which includes posters that can be printed out for back-of-house usage. They range from step-by-step instructions on proper hand washing to safety reminders for your operation’s kitchen.

It’s important to understand how to manage [ethylene], says Kate Burr, Markon’s Food Safety Director. “I believe it’s something operators and chefs learn from just being in the kitchen or in the distribution centers,” she adds.

“Berries, such as strawberries and blueberries, are not as sensitive to ethylene and will not produce much of their own ethylene when ripening,” she continues. “They can ripen at a controlled pace if they are exposed to other ripening fruits.”

Burr oversees Markon’s food safety department and 5-Star Food Safety Program, which both meticulously monitor fresh produce at the foodservice industry’s highest level. Ready-Set-Serve, Markon First Crop, and Markon Essential are the flagship products.

Here, Burr offers the following invaluable tips for foodservice professionals on how to properly manage ethylene gas. Maximizing produce shelf life is at top of mind, but also environmental considerations and safety.

- Some fruits are very sensitive to ethylene and will start to ripen as soon as exposed. The amount of ethylene needed to start the ripening process depends on the level of maturity of the fruit; for example, a very green banana would need more to “jump start” the process than a more developed banana.

- One way to slow down the ripening process is to maintain cooler temperatures and ensure correct cold change parameters are followed. If you have a controlled environment that has very little ethylene gas, you can control the ripeness levels of your product. Ethylene gas doesn’t survive well in very cold temperatures, so the refrigerator should be set between 34° F to 40° F. You also do not want the produce to freeze because that creates a whole new quality issue. And if the atmosphere gets too warm, the ripening process increases, and the quality of the product deteriorates at a much quicker pace.

- Ethylene is used to “de-green” citrus by triggering the breakdown of the green color of the peel, which causes the orange and yellow to become apparent. This is a continuation of the natural plant process.

- Some fresh produce responds well to external ethylene. For example, in a ripening facility for bananas, ethylene is added into the environment, which causes them to ripen at a quicker rate. If you were not to control any of the bananas’ temperatures while you’re shipping them, everyone would end up with brown bananas at the store. You must control their temperature as well as the ethylene to control that ripeness so you can get everyone that green or yellow banana they desire.

- Tomatoes, peaches, and pears are additional examples of fresh produce that is often picked when almost ripe. These fruits are shipped while still firm and less likely to damage. Then, distributors release ethylene into the warehouse storing the fruit, ripening them further before delivery to market. Because ethylene is flammable, extreme caution is advised when using it.

About Markon

Markon Cooperative, Inc. brings a fresh approach and thinking to all of its premium farm-to-table produce so foodservice operators can bring the freshest ideas to their consumers. Based in Salinas, California, Markon serves as the produce purchasing, logistics, information, and marketing partner for its five member distributors (Ben E. Keith Foods, Gordon Food Service, Gordon Food Service Canada, Nicholas & Company, and Shamrock Foods) and their North American foodservice customers. Learn more about Markon’s commitment to providing the highest-quality, safest, and freshest produce at Markon.com.

By Audarshia Townsend